Top

Description:

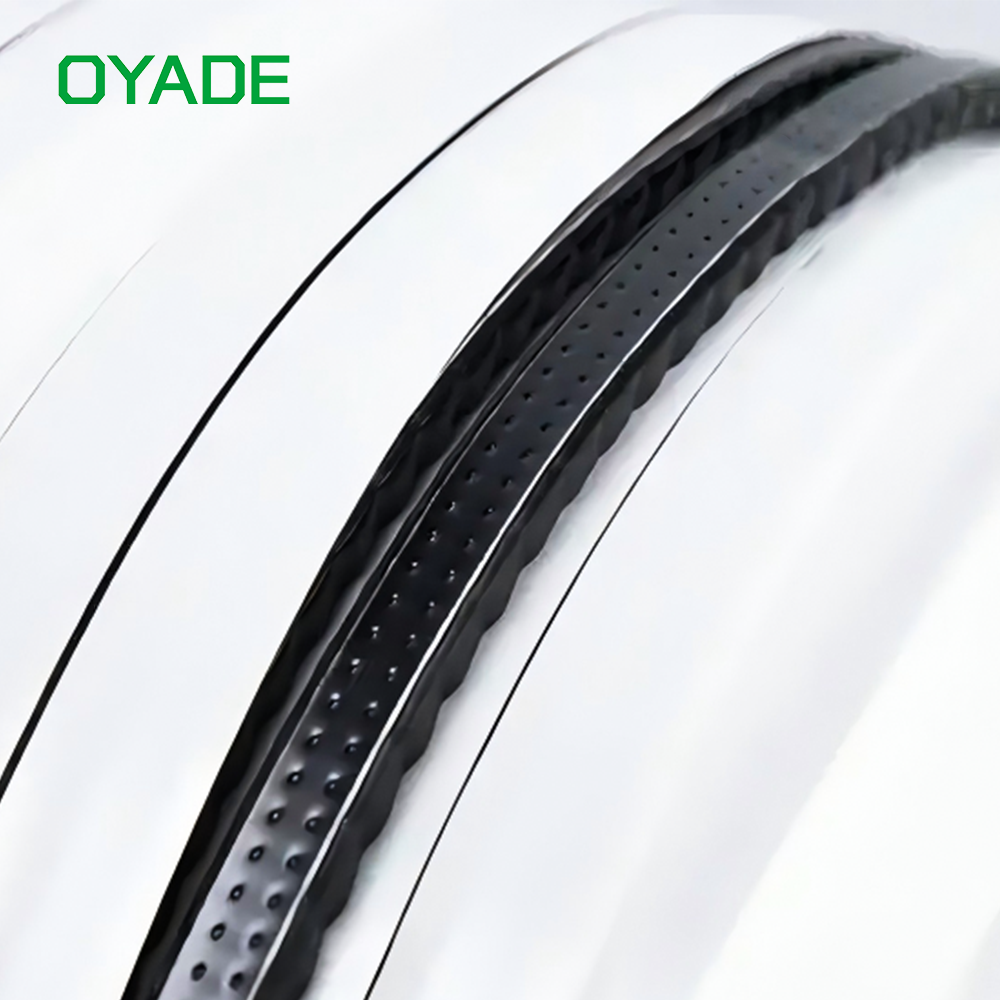

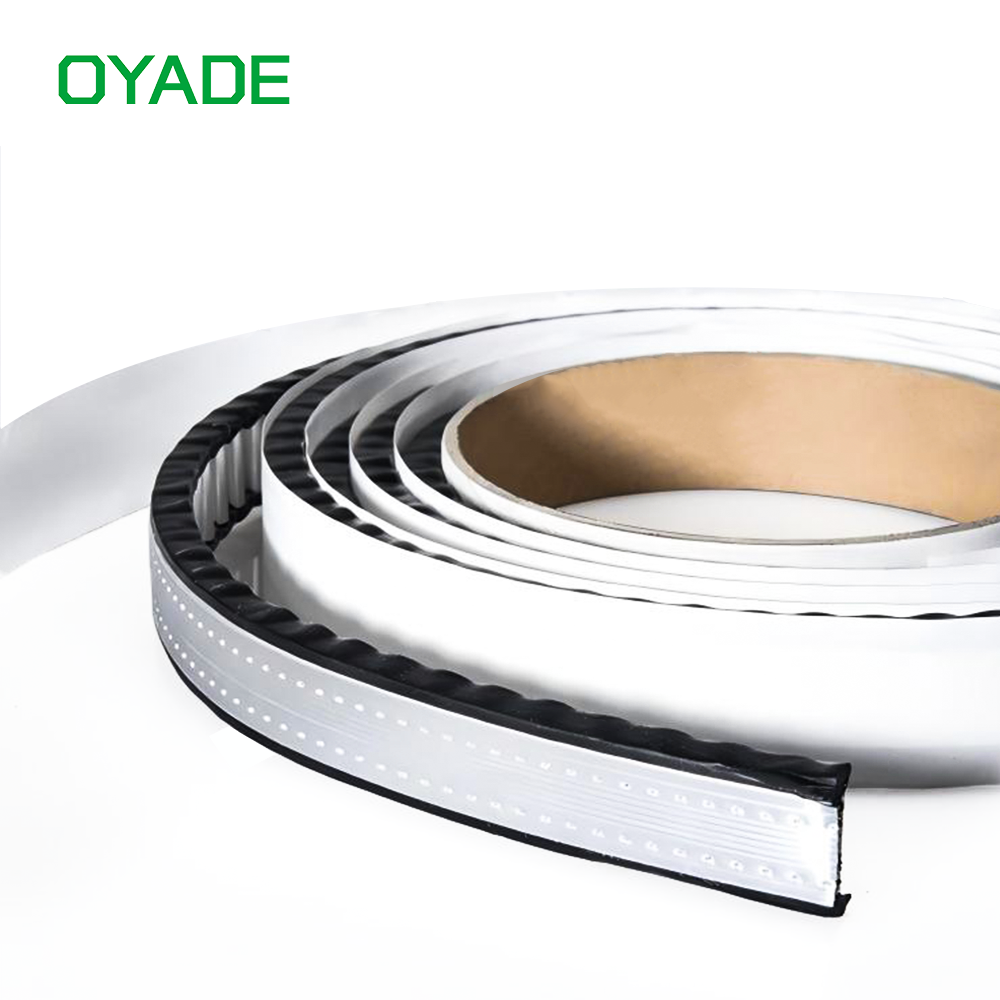

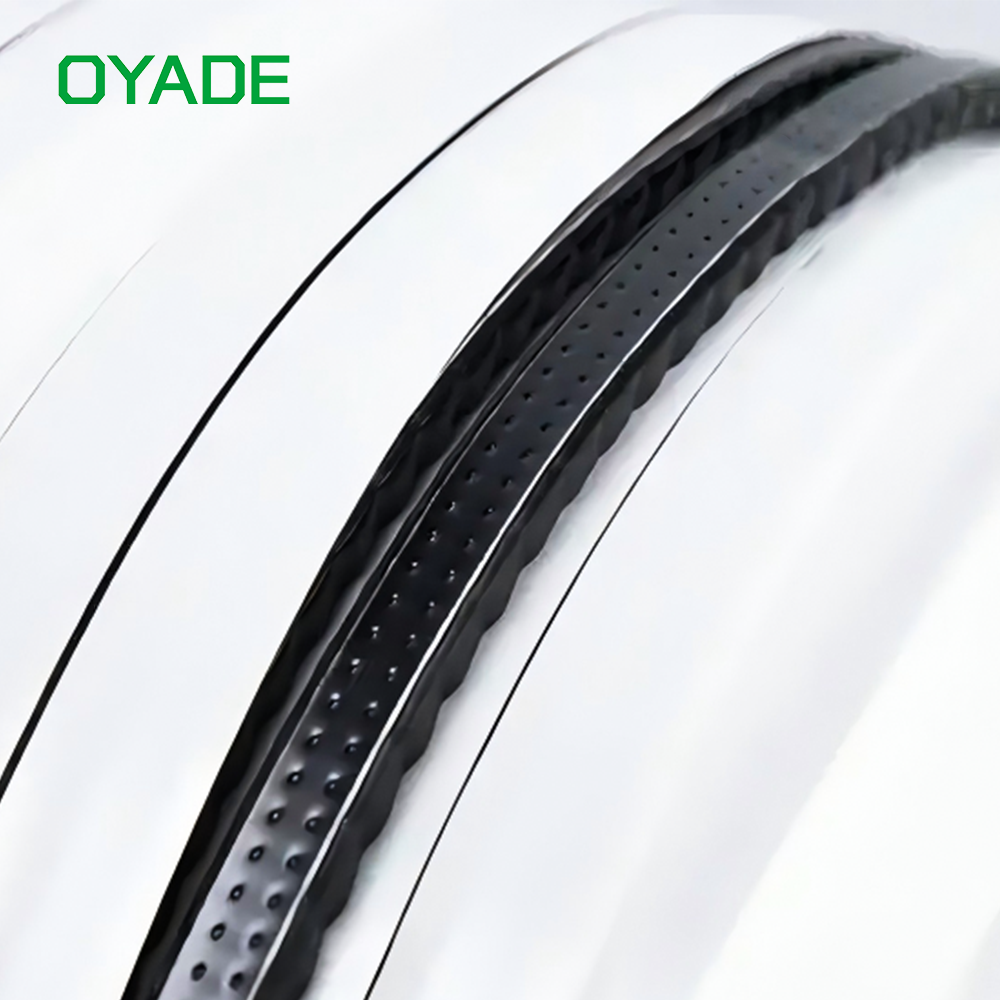

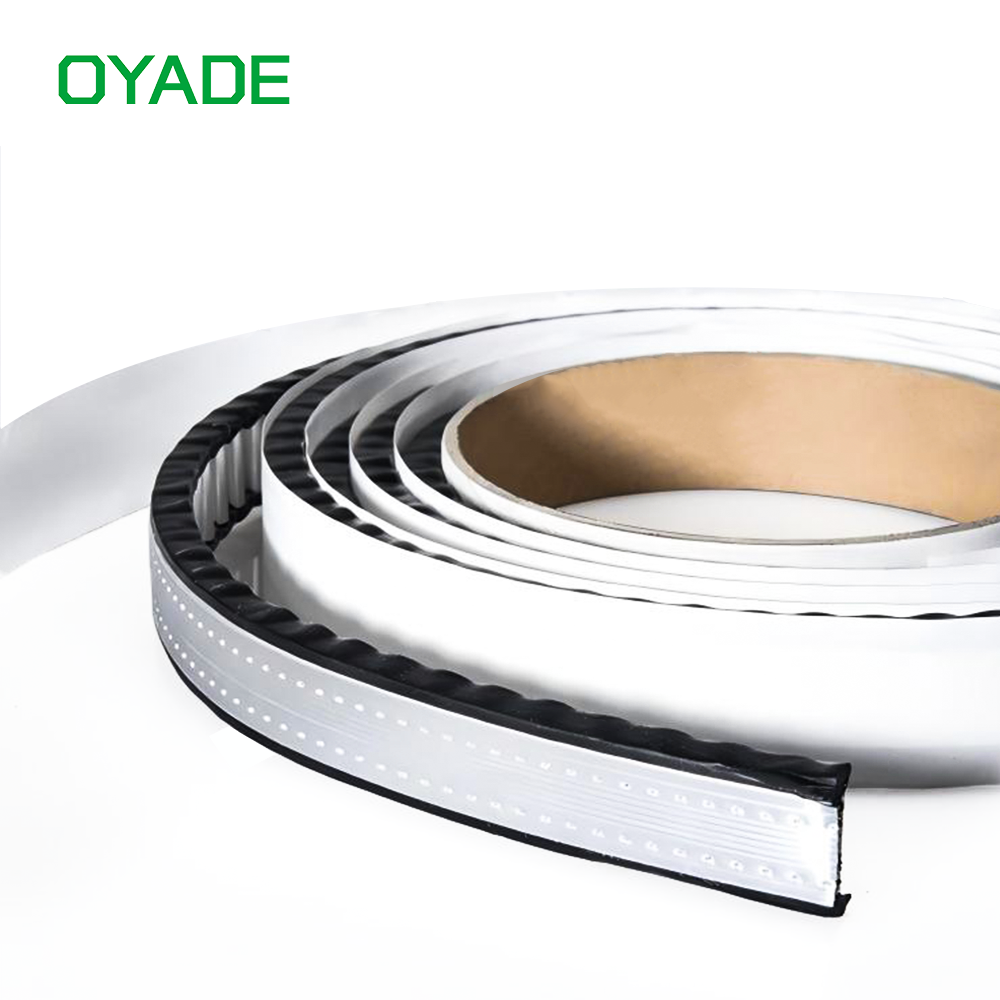

Super spacer is also called as composite butyl spacer bar. It is an an integrated spacer system made from high-strength aluminum spacer bar combined with premium butyl sealant and high-performance polymer adhesive. It offers exceptional tensile and compressive strength, equipped with a built-in molecular sieve, and requires no additional pins for connection. It also offers excellent weather and aging resistance. And its flexible structure flexes to the shape of the glass, making installation easier and extending its applicability.

Processing Technology:

One-piece construction integrating butyl sealant and polymer adhesive with a high-strength aluminum spacer bar.

Advantages:

1. High-gloss aluminum surface with excellent luster and an aesthetically pleasing finish.

2. Built-in high-percentage 3A molecular sieve for superior anti-condensation performance.

3. Can be bent to match any glass shape, extending its service life.

4. Excellent resistance to weathering, extreme temperatures, and aging for extended service life.

5. Simple production and installation process, convenient operation, and low cost, effectively improving construction efficiency.

Instructions:

1. Thoroughly clean the glass and dry it completely.

2. Leave 1.5 to 2 mm from the glass edge before applying it. Use a tool to apply the super spacer straightly, ensuring the edges are straight and the corners are 90 degrees to avoid wrinkles or twisting. Leave a 2 to 3 mm gap at the end of the spacers.

3. Heat-press the glass together with the super spacers. After pressing, check that the spacer temperature is between 43 °C–50 °C. Excessive temperature may cause excessive negative pressure, while insufficient temperature may reduce adhesion.

4. Seal the glass, ensuring the sealant strips are smooth, secure, and free of bubbles or gaps.

5. After confirming no gas leakage or other defects, apply secondary sealant where necessary. The insulating glass unit is then complete.