Top

OYD-A898 is a one-component, acetic acid, and room temperature curing silicone sealant. It has advantages of excellent waterproof, weather resistance, aging resistance and high, low temperature resistance, long service life, fast curing speed, high elasticity, high displacement capacity, and good bonding abilitys. After curing, it has high modulus performance and can bear ±25% telescopic displacement capacity.

Application:

1. Suitable for sealing and bonding of large glass panels, skylights, sun panels, etc.

2. Bonding and sealing of various large fish tanks and various glass assembly projects.

Limitations of Use:

1. Not to be used in structural bonding.

2. Not suitable for use in confined spaces or on surfaces in direct contact with food or drinking water.

3. Prohibited on painted surfaces as it may cause cracking or peeling of the paint film.

4. Avoid using it on surfaces where grease, plasticizers and solvents will seep out.

5. Do not contact with acidic or alkaline substances (e.g., exterior cleaning solution) to prevent discoloration.

6. Not applicable to calcium carbonate, iron, copper, cement, lime and other materials.

7. The sealing surface temperature should be between 4℃ and 40℃, beyond this range should be forbidden.

8. Not applicable to fireproof sealing system or areas susceptible to mechanical abrasion.

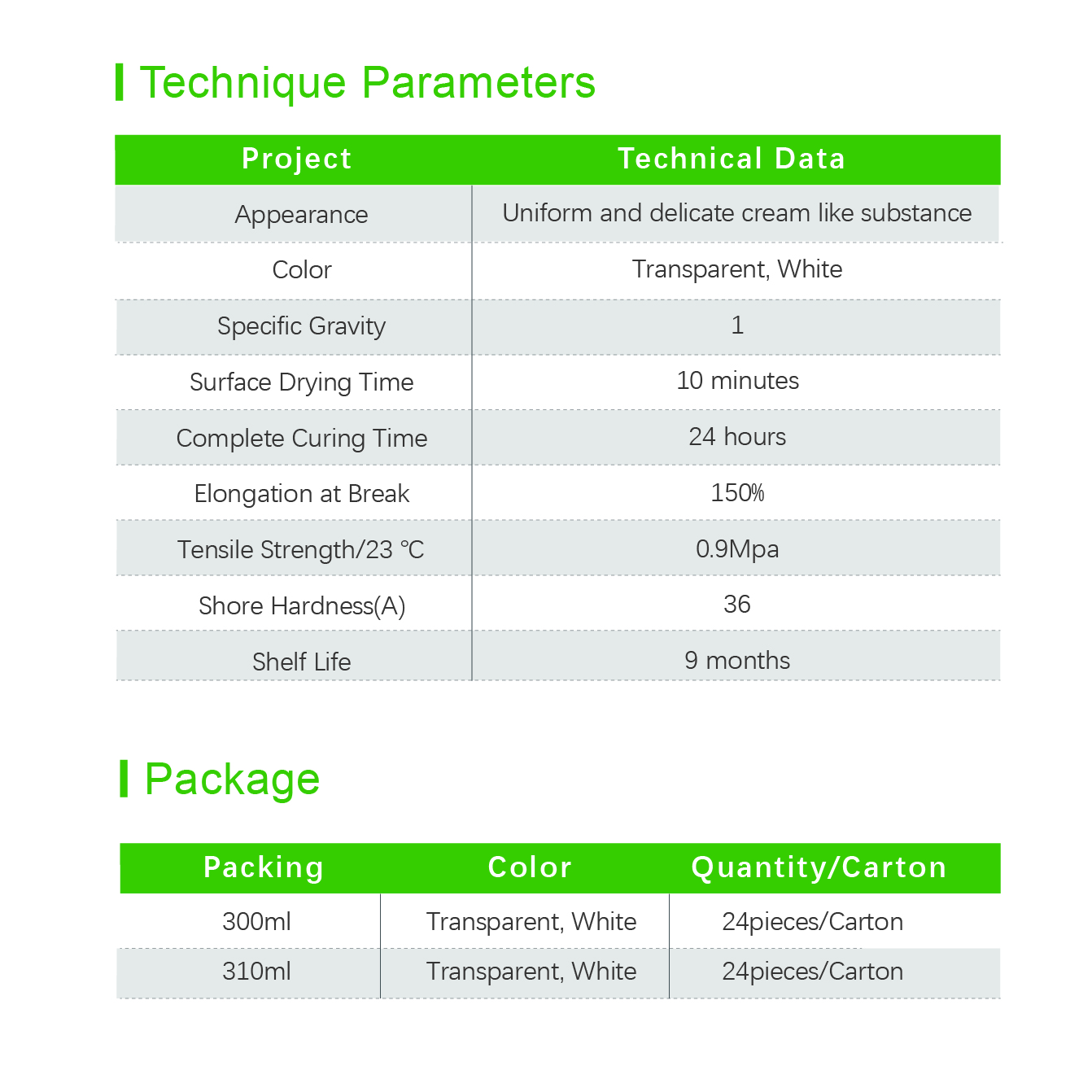

Shelf life:

It is a non-hazardous product, please store it in a cool and dry place with the temperature below 27℃ and the relative humidity should not exceed 50%.

OYD-A898 is valid for 9 months from the date of manufacture. And it is recommended to use it as soon as possible.

Method of use:

1. Use tools to clean the excess mortar residue, dirty oil stains, and protective coatings of the substrate surface.

2. According to the instructions, install the liner material or filler, liner bar barrier and tape.

3. Attach glue nozzle to the hose and cut the nozzle according to the size of the glue application gap adjustment.

4. Glue continuously and evenly to avoid air bubbles.

5. After gluing, flatten the sealant with appropriate force, and then trim the sealant surface into a concave shape with a convex tool. And do not use soapy water as an auxiliary material for trimming.

6. Tear off the masking tape immediately after finishing.

7. When assembling the glass, the sealant polished at the bottom interface needs to be trimmed into a bevel so that water does not flow.

8. If the uncured sealant and the interface of the non-porous material surface contact, it must be removed immediately with methyl ethyl ketone, toluene or xylene solvent before the sealant has cured.

Maintenance:

OYD-A898 begins to cure from the surface in contact with moisture in the air, and should be trimmed immediately after gluing.

The initial stage of glue application should keep the part that needs to be sealed fixed and leveled.

Generally no maintenance is required. If damage occurs, the cause should be identified first and targeted repair.

Safety Notes:

This product is non-toxic and harmless to human body after fully cured. But you still should pay attention to the following:

1. Do not put the sealant together with food and cosmetics.

2. Uncured sealant should not come into contact with skin for prolonged periods of time.

3. If you accidentally get the sealant into eyes, you must immediately rinse with a lot of water and seek medical attention.

4. Ensure ventilation in the use environment.

5. Please place the product out of reach of the elderly and children.

Warm tips:

During the curing, the temperature difference between day and night on the substrate surface or the thermal expansion and contraction of the substrate will cause changes in the glue joint. This can easily cause the surface of the glue joint to be uneven, i.e., bulging. In order to achieve satisfactory results, the gluing experiment is necessary in line with the requirements of the large-scale construction.