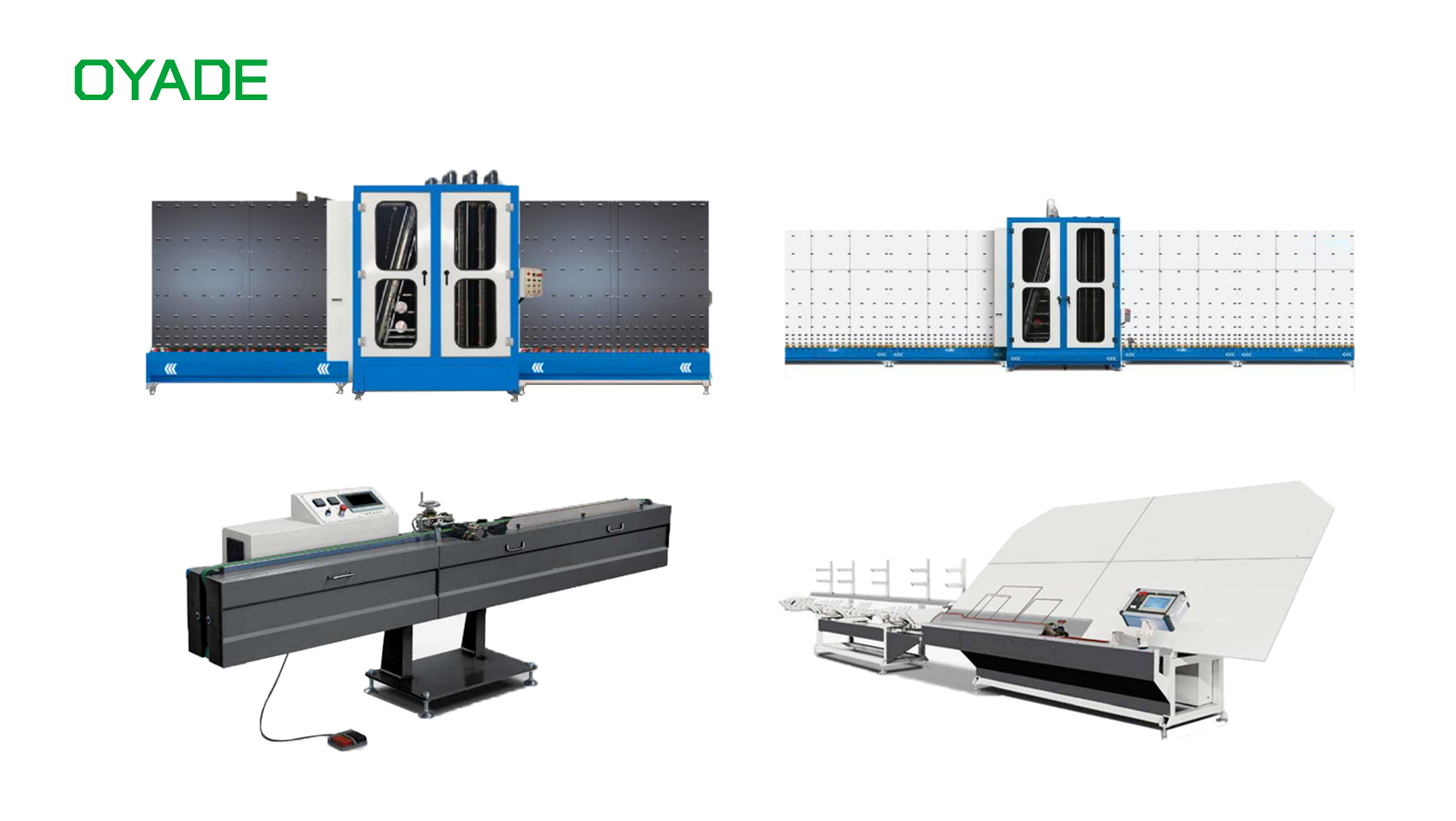

OYADE will Launch Full Line of Insulating Glass Processing Equipment

At OYADE, we understand that efficiency, precision, and reliability are critical for insulating glass production. That’s why we’re excited to introduce our latest expansion: a full range of glass processing machines engineered to meet the diverse needs of IGU manufacturers — from small workshops to large-scale industrial facilities.

Our new equipment lineup covers every major step in the production of high-quality insulating glass, including:

1. Georgian Bar Milling Machine

It is specialized for diamond-shaped Georgian bar. It is ideal for building materials and furniture decoration industries. It enables efficient and precise grooving, and improves the bar quality and aesthetics.

2. Georgian Bar Staple Table

It is designed for Georgian bars splicing and widely used in the field of building materials and furniture decoration. With precise structure and functions, it enables efficient and stable splicing of diamond, square, and other Georgian bars, enhancing splicing quality and efficiency.

3. Georgian Bar 45° Angle Cutting Machine

It is designed for cutting Georgian bars. It is widely used in serving building materials, furniture making and interior decoration industries. It can precisely cut 45°angles and provide good joints for splicing and assembly, improving product aesthetics and quality.

4. Georgian Bar Drilling Machine

It is also called Georgian bar holing machine, which is specialized in diamond-shaped Georgian bar drilling. It serves furniture making and interior decoration industries. And it can drill holes efficiently and accurately, making Georgian bar more unique appearance and function to meet the diverse needs of customers.

5. Film Removal Machine

It efficiently and precisely removes films from glass, metal sheet, and plastic sheet, boosting processing efficiency and facilitating subsequent procedures.

6. Aluminum Spacer Bar Bending Machine

Automatically bends spacer bars into rectangular, square, or shaped IGU formats with minimal error and high speed.

7. Molecular Sieve Filling Machine

Quickly and accurately fills aluminum spacer bars with desiccant to prevent internal condensation.

8. Butyl Extruder (Butyl Coating Machine)

Ensures uniform application of butyl sealant on spacers, providing strong initial adhesion and superior airtightness.

In Summary

With the addition of our new glass processing equipment, OYADE is now fully equipped to support insulating glass production from start to finish. Whether you're upgrading your current line or launching a new facility, our scalable, high-performance machinery and complete range of accessories ensure that you have everything you need in one trusted partner. At OYADE, we’re committed to delivering reliable quality, technical expertise, and solutions that grow with your business.